A Look Inside Aarson’s Production Process: Crafting Quality Garments

Aarson Uniform and Garment has built a strong reputation for producing high-quality garments, particularly uniforms, that meet the needs of diverse industries. From precision in design to the final stitch, the company’s production process is a well-oiled machine where quality control, attention to detail, and innovation all come together. Here’s an in-depth look at how Aarson achieves its exceptional craftsmanship in garment production.

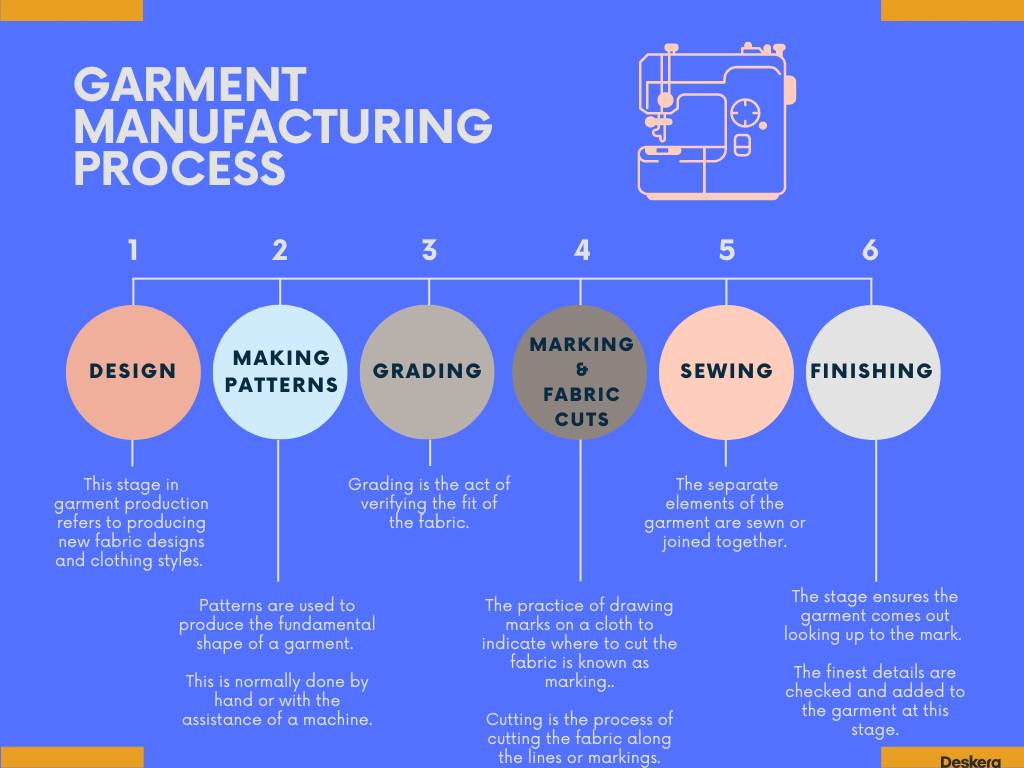

1. Design and Planning: Laying the Foundation

The production process begins long before the fabric meets the sewing machine. It starts with the design phase, where Aarson’s team of designers collaborates closely with clients to understand their specific needs. Whether it’s a corporate uniform, hospitality attire, or industrial workwear, the design is tailored to fit the purpose.

Aarson’s design team uses advanced software to create patterns that not only meet functional requirements but are also stylish and comfortable. This design blueprint includes precise measurements, fabric types, color schemes, and any other custom specifications needed. After final approval from the client, the production planning stage kicks in.

Key Elements in Design and Planning:

- Consultation with clients to understand their needs.

- Tailored designs focusing on functionality and aesthetics.

- Advanced design software to create precise patterns.

2. Material Selection: The Foundation of Durability

Aarson understands that the quality of the final garment depends heavily on the fabric chosen. Therefore, a great deal of attention is given to selecting the right materials. Whether it’s a sturdy polyester blend for corporate uniforms or breathable cotton for hospitality attire, the choice of fabric is critical to comfort, durability, and ease of care.

Aarson sources materials from reputable suppliers, ensuring that every fabric used meets strict standards for quality and consistency. The company also strives to incorporate sustainable materials where possible, aligning with global trends toward eco-conscious production.

Material Selection Highlights:

- Sourcing from trusted suppliers for consistent quality.

- Careful selection of fabrics based on garment function.

- Focus on sustainability with eco-friendly material choices.

3. Cutting and Pattern Making: Precision in Every Cut

Once the design and materials are finalized, the next step is cutting the fabric according to the established patterns. Aarson utilizes both manual cutting methods for custom designs and automated cutting machines for larger production runs. The precision in cutting ensures that each garment component fits perfectly, which is vital for ensuring the uniformity and comfort of the final product.

Pattern making plays a pivotal role here. Experienced pattern makers at Aarson create templates based on the design specifications. These patterns are then used to cut the fabric in the exact shapes and sizes required.

Cutting and Pattern Making Features:

- Combination of manual and automated cutting methods.

- Experienced pattern makers for accurate and consistent results.

- Focus on precision to ensure the perfect fit.

4. Sewing: The Heart of Garment Production

The sewing stage is where the magic happens. At Aarson, skilled seamstresses and machinists work meticulously to assemble each garment. The company uses advanced sewing machines that offer a variety of stitch options, ensuring that each garment is both durable and comfortable.

During this stage, the fabric pieces are stitched together with high attention to detail. Aarson ensures that the stitching is not only aesthetically pleasing but also strong enough to withstand the wear and tear associated with uniforms. Reinforced stitching is applied in areas that endure the most stress, such as cuffs, hems, and seams.

Sewing Process Insights:

- Highly skilled seamstresses ensure quality stitching.

- Use of advanced machines for variety in stitching techniques.

- Reinforced stitching for added durability and strength.

5. Quality Control: Ensuring Perfection

After the garments are sewn, they go through rigorous quality control procedures to guarantee they meet Aarson’s high standards. Each piece is thoroughly inspected for any defects, from fabric flaws to stitching irregularities. Garments are checked for proper fit, color consistency, and overall craftsmanship.

Aarson follows a stringent multi-step quality assurance process, which includes visual inspection, fabric testing, and wearability assessments. This step ensures that the garments are durable, comfortable, and free of any defects before they are sent for final finishing.

Quality Control Features:

- Thorough inspection for defects and irregularities.

- Multi-step quality assurance process to guarantee consistency.

- Testing of fabric and finished garments for durability.

6. Finishing Touches: Adding the Final Flair

Once the garments pass quality control, they move on to the finishing stage. This involves adding any necessary embellishments, such as logos, embroidery, or other customizations. Aarson uses state-of-the-art embroidery machines to apply company logos and text with precision, ensuring a professional and polished appearance.

The garments also undergo final pressing to remove any wrinkles, ensuring they’re ready for delivery. The finishing touches are what truly elevate the garments, making them look sharp and neat while maintaining their comfort and durability.

Finishing Touches Highlights:

- Custom embroidery for logos and branding.

- Final pressing to ensure a crisp, professional look.

- Adding any additional custom elements to the design.

7. Packaging and Delivery: Ready for the World

Once the garments are completed, they are carefully packaged to ensure they reach their destination in perfect condition. Aarson uses high-quality packaging materials to protect the garments from damage during transit. Special care is taken to fold and wrap each uniform to ensure it arrives looking fresh and ready for wear.

The company also works with reliable delivery partners to ensure timely and secure shipments. Whether delivering to a local business or an international client, Aarson ensures that every garment reaches its destination in pristine condition.

Packaging and Delivery Process:

- Careful packaging to protect garments.

- Reliable shipping partners for timely delivery.

- Attention to detail in preparing garments for shipment.

8. Customer Feedback and Continuous Improvement

The final step in Aarson’s production process involves gathering feedback from clients. Aarson values customer input, which is used to make improvements and refine their processes. By continuously learning from client experiences, Aarson is able to stay at the forefront of the industry and maintain its reputation for high-quality production.

Feedback and Improvement Process:

- Gathering customer feedback for future improvements.

- Implementing changes based on client input.

- Continuous refinement of production processes.

Conclusion

Aarson Uniform and Garment’s production process is a testament to the company’s commitment to quality, innovation, and customer satisfaction. By combining advanced technology, skilled craftsmanship, and attention to detail, Aarson ensures that every garment produced not only meets but exceeds expectations. The result is a range of uniforms that are stylish, functional, and durable, crafted to serve businesses and industries across the globe. Whether it’s for a corporate office, hotel, or factory floor, Aarson’s garments are a symbol of excellence in every stitch.